LOCATION : HOME > News > Company news

Zhongrui condensing waste heat steam boiler

user:admin time:2018-11-21 view:3570

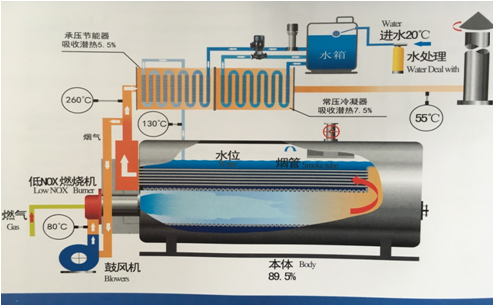

(1) Pressure-bearing design, boiler hydration can directly pass through the pressure-saving economizer, fully absorb the sensible heat in the flue gas, and can increase the boiler hydration temperature to above 130 °C.

(2) A radial aluminum sheet with excellent thermal conductivity is attached to the surface of the tube to obtain a large heat transfer area under a small volume condition.

(3) The material of the economizer base pipe is ND steel, which is resistant to corrosion and has a small amount of thermal expansion and contraction. It can be said that it is a long-life device.

3. Application system

The condensing heat exchanger of the condensing waste heat recovery boiler is connected with the hot water tank and circulated and heated by the circulating pump, and then injected into the boiler through the economizer through the water pump. It is suitable for central heating buildings that use heating and large amounts of domestic hot water, general hospitals, Hotel, health center, or centralized steam supply unit. The efficiency of the boiler itself cannot be improved, but the waste heat of the boiler exhaust is absorbed by domestic water, thereby achieving a comprehensive benefit of energy conservation and environmental protection.

4. What is the variable frequency condensing waste heat recovery boiler

In general, boilers with a thermal efficiency of more than 100% are difficult to understand on common sense. If the latent heat of condensation of water vapor in the flue gas is utilized, and the exhaust gas temperature is lowered sufficiently, and the exhaust gas is low, the thermal efficiency of the boiler is low. Will increase to more than 100% (the thermal efficiency of the boiler is calculated using the high calorific value of the fuel)

Of course, it is impossible to calculate the thermal efficiency of the boiler according to the calorific value of the fuel. The high efficiency condensing heat exchanger and economizer are used to absorb the sensible heat and steam condensation in the exhaust of the boiler tail. The latent heat released, so as to achieve the purpose of improving the thermal efficiency of the boiler. The frequency converter is used to realize the continuous water supply of the boiler, and the frequency conversion proportional combustion, which becomes the frequency conversion condensing waste heat recovery boiler.

Boiler thermal efficiency analysis:

Theoretical efficiency in sensible heat and latent heat recovery in flue gas

Boiler efficiency at 260 ° C exhaust gas temperature: 89.5%

Increase efficiency when primary condensation latent heat recovery: 5%

Increase efficiency when secondary condensation heat recovery: 7.5%

Theoretical thermal efficiency of the condensing boiler: 102.5%

5. Condensation waste heat recovery steam boiler

Structural features

1. The body is a two-pass wet-back structure;

2. Add double energy-saving devices at the tail: (1) The first stage is the slab tube type pressure-conserving energy saver (2) The second stage is the atmospheric pressure condenser

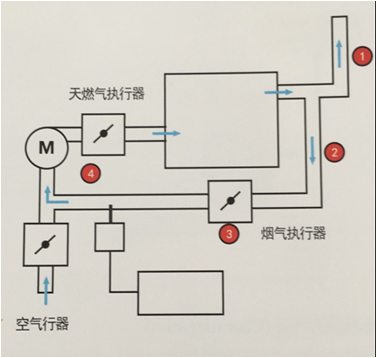

3. Adapted to high quality low NOX burner, low combustion and low emissions; (1) FGR system provides combustion wind (2) FGR backfire system to ensure low nitrogen emission of burner

4. The boiler adopts advanced color touch screen control system;

5. Using variable frequency continuous water supply technology

6. Using proportional frequency conversion combustion technology

7. With air pressure, water level automatic adjustment function, automatic ignition, and water shortage, over pressure, flameout protection.

8. The overall fast loading factory. Beautiful appearance.